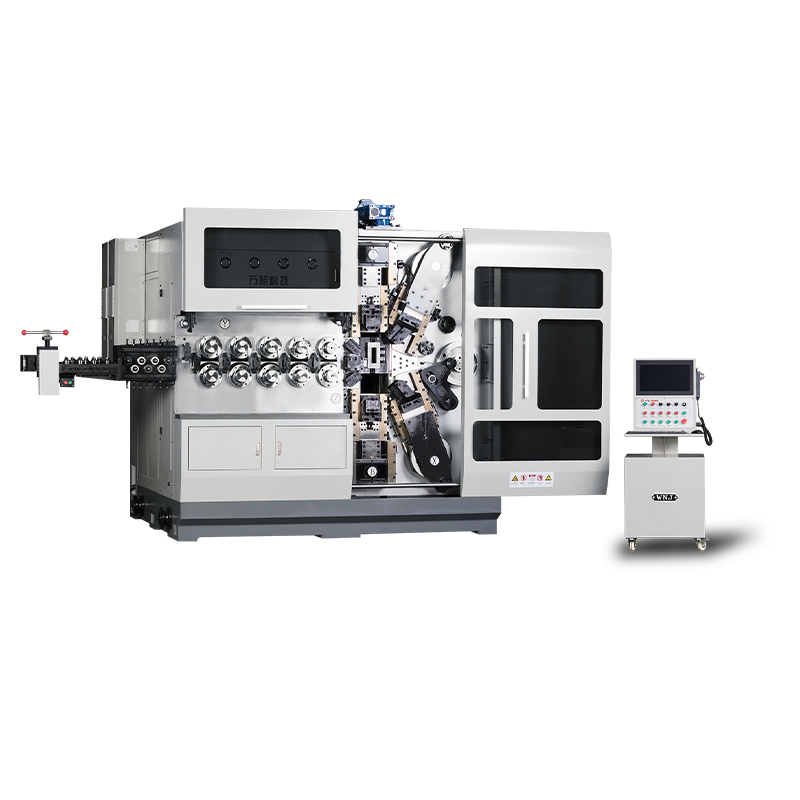

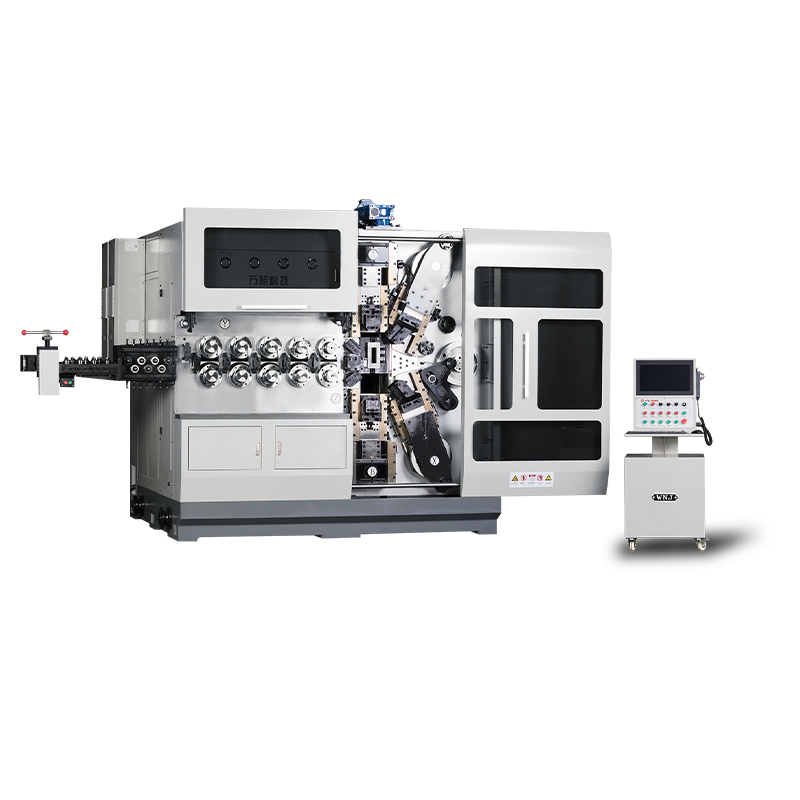

With the development of the modern industrial field, more and more enterprises have begun to pay attention to the use of mechanized production methods to improve production efficiency. Among them, the precision

spring machine has received extensive attention and application as a high-precision and high-efficiency production tool.

1. Definition and classification of precision spring machine

Precision spring machine refers to the machine equipment that can quickly and accurately manufacture various shapes of metal wire springs. According to its structure and production method, it can be divided into two categories: convoluted spring machine and pressure spring machine.

The convoluted spring machine is mainly composed of a wire inlet shaft, a crimping table, a cutting table, a crimping tool, etc. The coiling table is rotated in one or two directions so that the wire is gradually formed in the process, and finally the cutting table is cut to complete the whole process. work process.

The pressure spring machine uses the principle of a press to produce springs by stamping and forming on a steel plate. Common pressure spring machines include four-column presses and six-column presses.

2. Working principle of precision spring machine

When the convoluted spring machine is working, the wire is sent from the incoming shaft to the crimping table through a set of rollers. The crimping table rotates at a certain speed to curl the wire into the desired shape, and then passes through the scissors of the cutting table to complete the cutting. During the whole working process, the machine can also complete the adjustment and control of the spring ring number, height, diameter and other dimensional parameters.

The pressure spring machine uses steel plate stamping to form springs to produce springs. Its working principle is: put the processed steel plate on the workbench, and under the clamping of the upper and lower pressure heads, perform the stamping action to complete the forming. The compression spring machine is suitable for the production of springs of various shapes, with high production efficiency and high precision, but it requires more manufacturing costs.

3. Application range of precision spring machine

Precision spring machines are widely used in industries such as automobiles, military industry, aerospace, electronics, instrumentation, and home appliances. With the continuous and in-depth development of industrialization and informatization, there are more and more applications for precision spring machines, especially in high-precision industries such as auto parts and electronic components.

4. Advantages and development trends of precision spring machines

Compared with the traditional way of making springs by hand, the precision spring machine has the advantages of high efficiency, stable quality, large production scale and good repeatability. With the continuous advancement of science and technology, the precision spring machine is also constantly being upgraded in a more intelligent and automated way, such as changing the manual adjustment of size parameters to automatic detection and control, which further improves its production efficiency and accuracy. It provides more efficient, stable and reliable mechanical support for the industrial production of enterprises.

At the same time, with the development of high-end manufacturing industry, the requirements for precision spring machines are getting higher and higher. In the future, precision spring machines will develop in the direction of high speed, high precision and high automation, and adopt more advanced control technology and material technology to meet the needs of various industries in the field of high-quality and high-efficiency production.