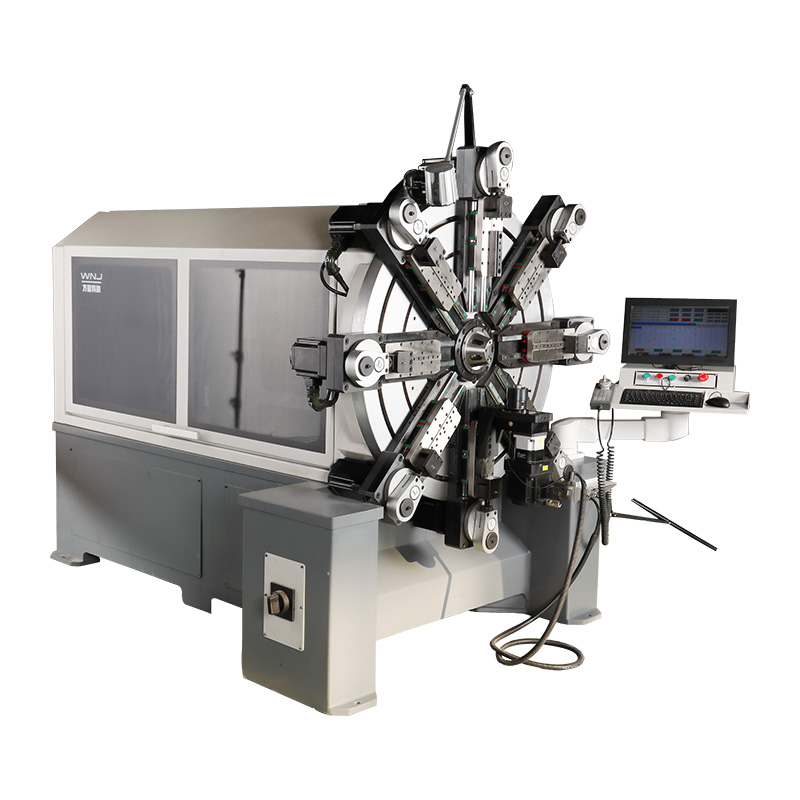

Tower spring is one of the most widely used spring products in the industrial industry. At this stage, most hardware fittings or spring factories often produce this kind of spring products. Warm reminder, according to the structural characteristics of the tower spring itself, we need to select the relative compression

spring machine for debugging and winding. So, how to debug the winding tower spring of the compression spring machine?

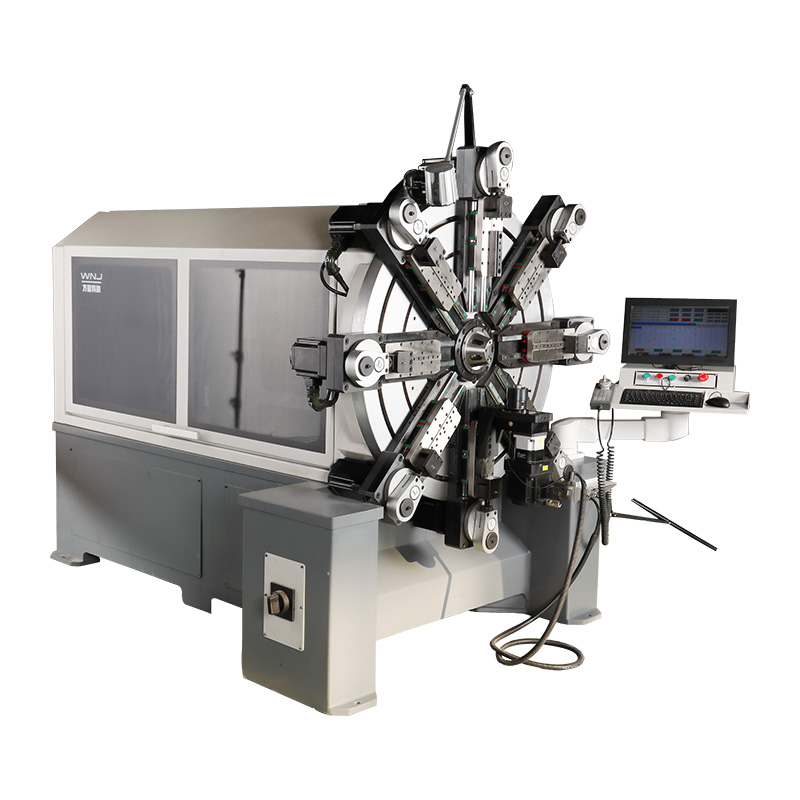

① Observe the structural characteristics of the tower spring and master the pitch of the starting point. Throughout the commissioning process, the pitch of the spring should open or close on a certain circumference. The root cause of this spring is generally to tilt in a certain direction after settling. Therefore, in the actual operation of using the compression spring machine to wind the tower spring, we must pay attention to this.

②Master the winding characteristics of the tower spring and control the change of the diameter. Since the tower spring is variable during the entire winding process, it is necessary to adjust the diameter of the gap in the actual commissioning operation, and then install the reducing camshaft and adjust the proportional rod for maintenance. Not only must the spring be operated correctly. As the diameter changes, the spacing between the coils must also be adjusted.

③ During the whole process of debugging the tower spring, it is necessary to grasp the overall height of the prefabricated components. During the whole process of debugging and winding the tower spring with the spring compression machine, the overall height of the tower spring is controlled and adjusted according to the control of the pitch and the adjustment of the diameter. Suppose you want to grasp the market price of a compression spring machine.

④Adjust the diameter of each coil to ensure flatness and coaxiality. During the whole process of debugging and winding the tower spring, special attention should be paid to the specification of its diameter. During debugging, it is necessary to go through continuous attempts to clarify the size of each diameter, such as the effective statistics of short head diameter, medium diameter, big end diameter, prefab height, etc. Otherwise, the spring will stick out due to the middle diameter after setting. In turn, the flatness and coaxiality of the spring itself are threatened.

In addition, the tower spring must withstand the necessary working pressure when in use. The two sides of the structure are divided into open, closed and wound. Due to the different sections of the raw materials, it is divided into ring, rectangular frame and multi-core steel winding; due to the difference in pitch, it is divided into equal pitch and variable pitch. Therefore, in the whole process of winding the tower spring, you can refer to the described solution to give full play to the function of the compression spring machine.